[ Die Casting ]

- Material:Zinc, Aluminum, copper, Steel, Stainless steel

- Capacity:138 to 350 tons (X6)

- Complete secondary M/C

- Value added assembly

- Mold flow & stress analysis software

- Miscellaneous capabilities : Deburring, polishing, sand blasting, painting, coating

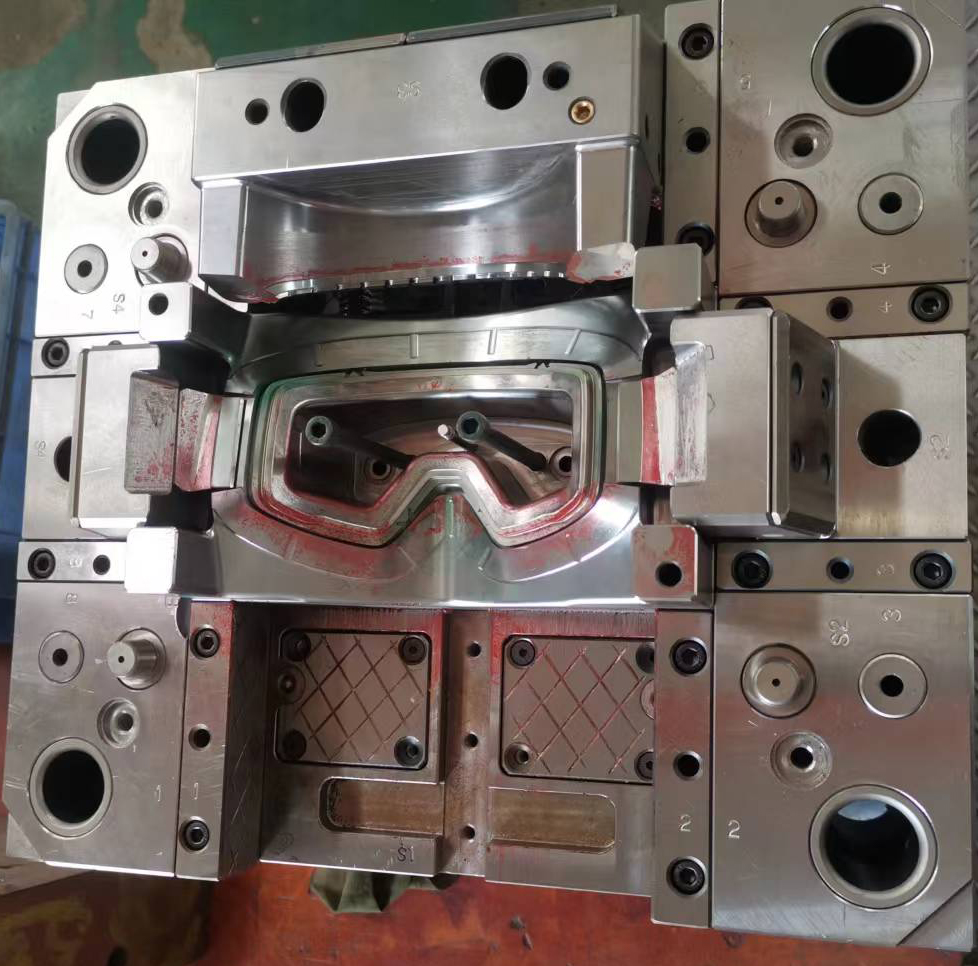

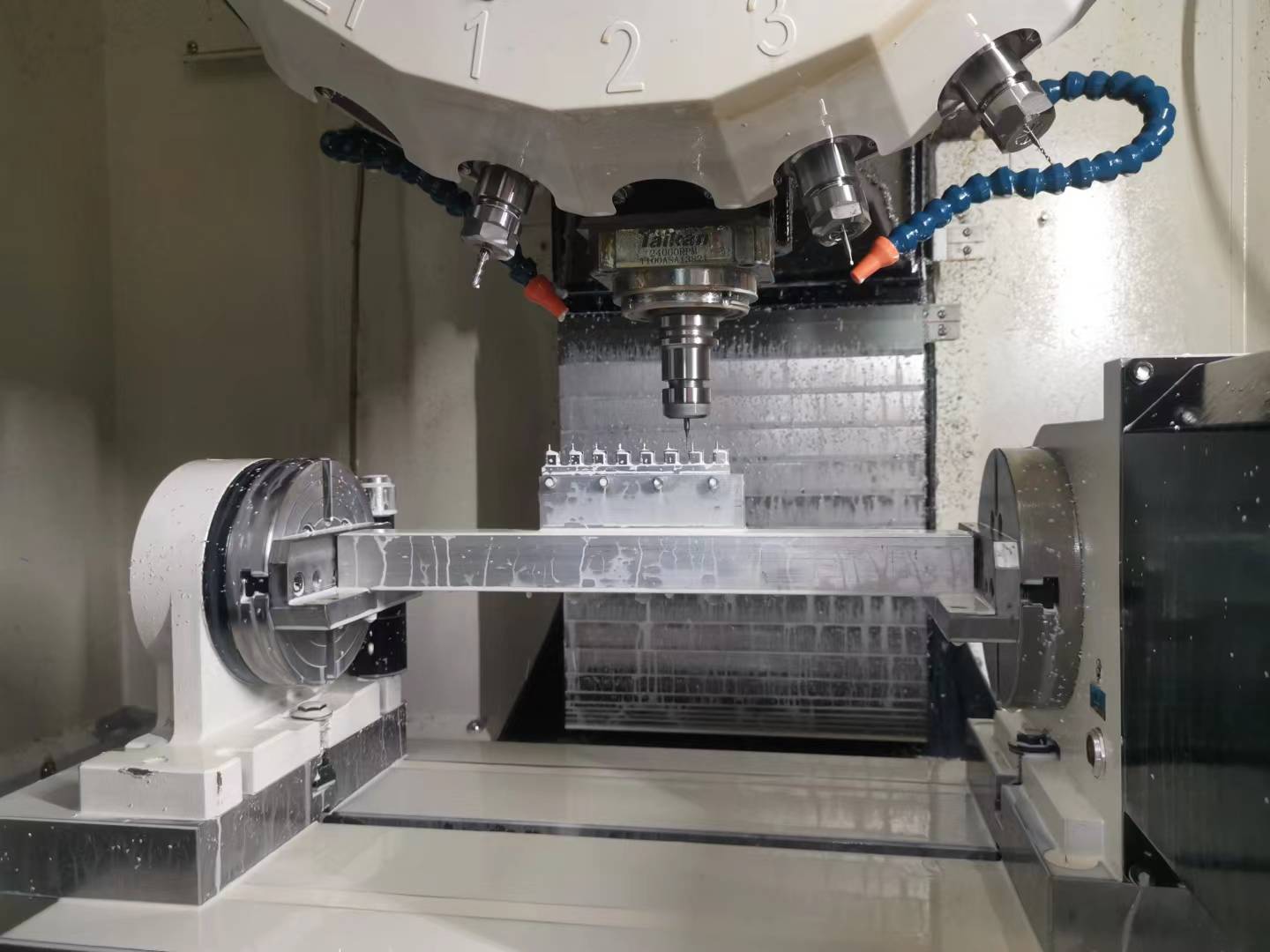

[ CNC Lathe / Machining ]

- From 0.4mm-30mm diameter and 2mm-1000mm long

- Advanced CNC lathes

- Supportive CNC machining

- Automatic lathes

- CNC lathe : 13 sets(Star SB-20J type E)

- Self centering cylindrical grinding

- Secondary machining capabilities

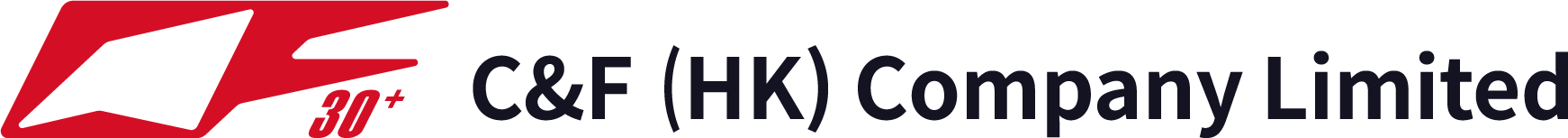

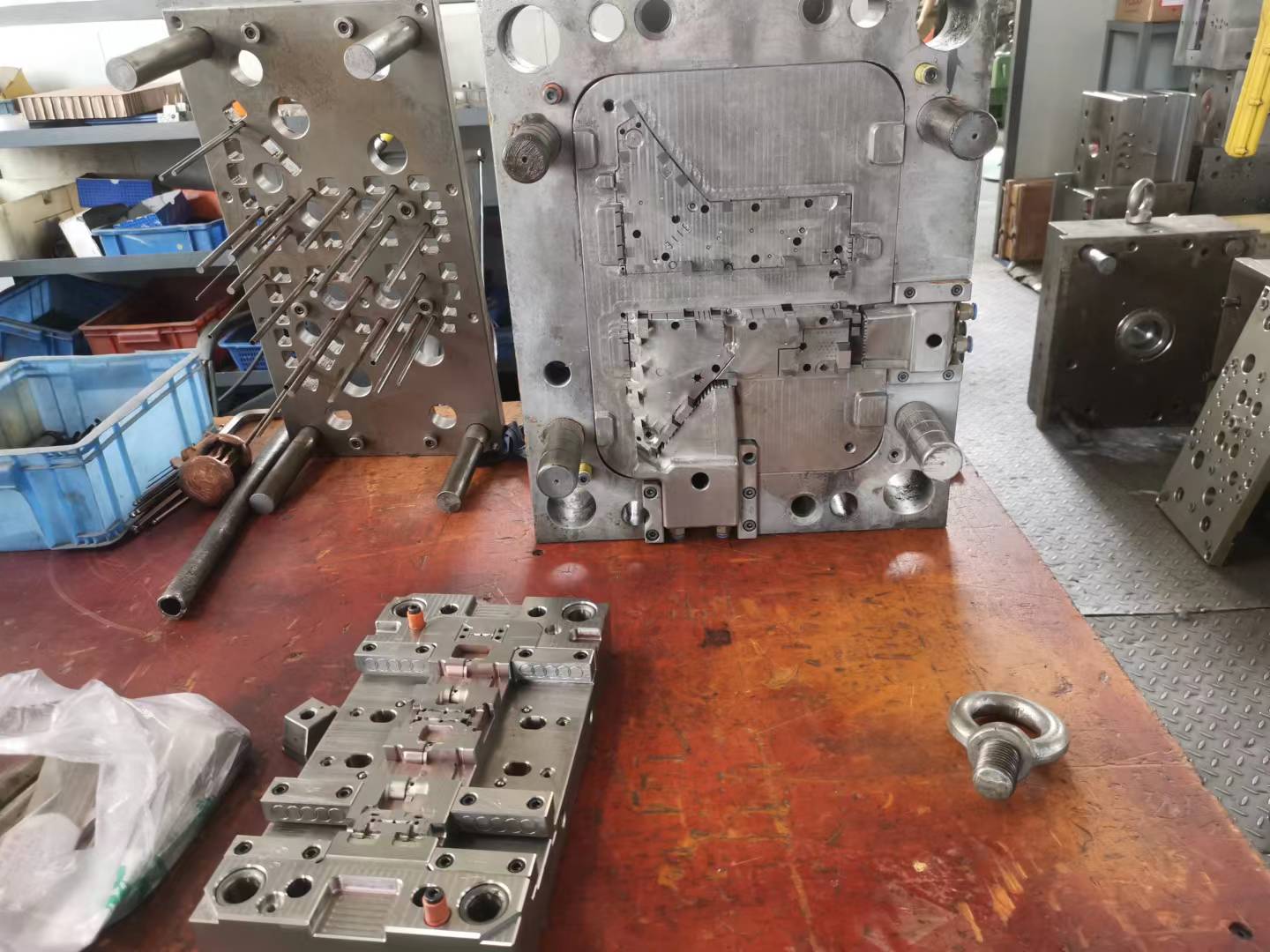

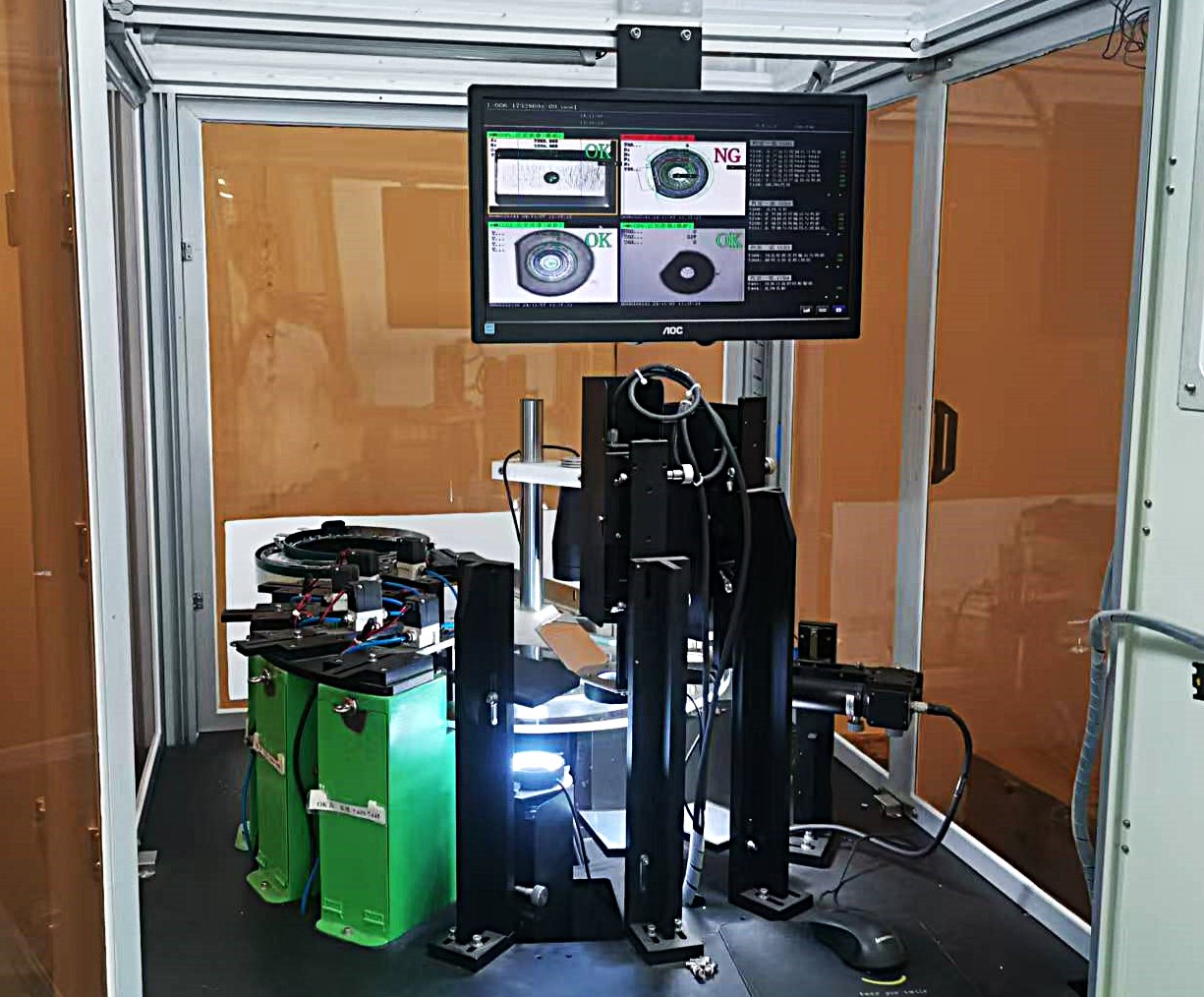

[ Stamping/CNC machine ]

- Complete tool design & build facilities

- Progressive die stamping

- CNC machine(x9)

- Machine capacity to 200 tons(x24)

- Medium to high volume

- Deep draw capability(x2)

- Laser welding

- dust-free plant(x3)

- Value added assembly, welding, staking, drilling & tapping, silkscreen printing

[ CNC Punching & Laser cutting M/C]

- Main facilities :

- 1 - AMADA Laser Cutting M/C(AMADA)

- 1 - NCT Punching M/C(AMADA)

- 4 - AMADA Bending M/V(AMADA)

- 3 - Stamping M/C 16T to 200T

- 1 - Brushing M/C

- 1 - Butt welding M/C

- 3 - Collision welding M/C

- 2 - Revising M/C

- 5 - Argon arc welding M/C

- 2 - Ultrasonic washing M/C

- 3- Drilling /Tapping M/C